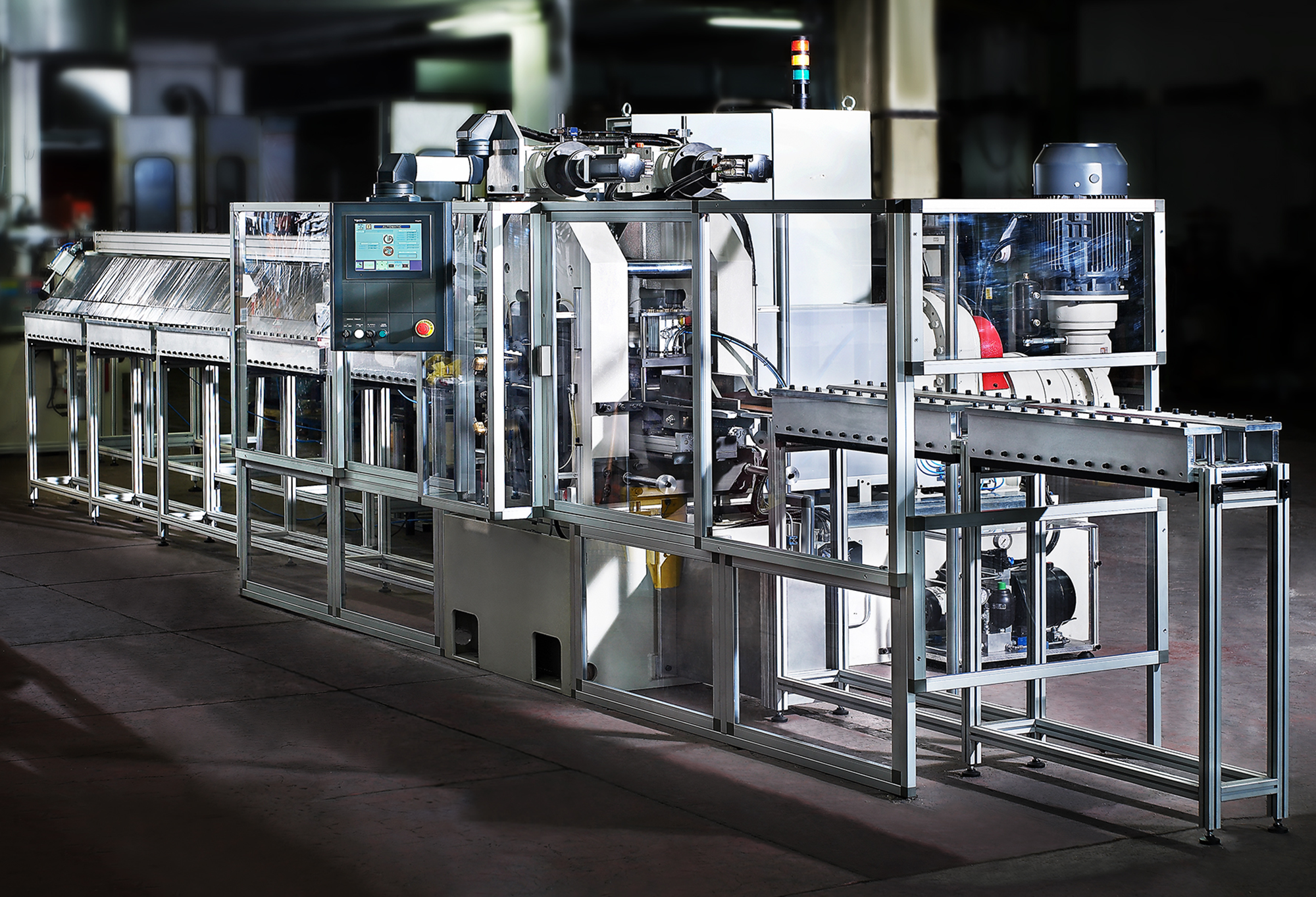

Rolling Mill Machinery

Who we are

Famor Srl is an Italian company specialized in the design and construction of cold rolling plants born in 1986. Born to meet the efficiency and productivity needs of the major gold and silversmith firms in the area, it has developed considerable experience over the decades. in the lamination of metals and different materials such as gold, silver, platinum, precious metals, non-ferrous materials, special alloys, super conductors, stainless steel, electrical contacts, dental alloys, catalysts. The Lean tools that have been introduced and that are implemented every day are the following: Kanban, Gantt Chart, PPM, PQP, 5S, OEE, Asa-Ichi Meeting, Kaizen, Just In Time, VSM, PDCA. The biggest challenge faced by the company throughout its history has been to make the lamination process automatic and to ensure its accuracy during all phases. For this purpose it is good to remember that the quality of Famor Srl brand machines is linked to a particular attention to the customer's needs during the product design phase.

- CAD 2D & 3D Systems

- FEM Analysis

- Material Choices

- PLC & Touch Screen

- Thickness Control

- Brushless Motors

English

English  Italiano

Italiano